Likely increase in performance of your cable compared to a cable with the least favourable choices for all the parameters. Performance is an indicator of both qualitative aspects such as reliability and quantitative aspects such as generation.

The benchmark generation is the generation of the solar cable with the least favourable choices for all the parameters.

The benchmark cost is the cost of the solar cable with the least favourable choices for all the parameters.

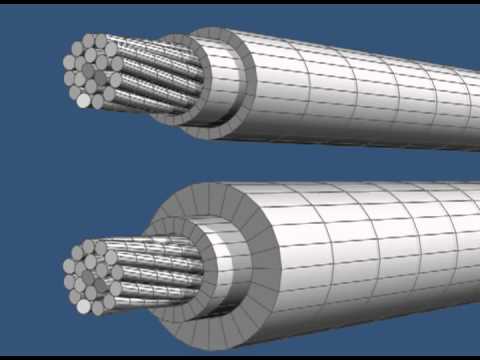

Cables

The electricity transfer medium

Cables used in solar power generation are slightly different from the conventional electric cables. Solar cables are designed to withstand long-term exposure to sunlight. The following are the key parameters you should use to select the right cable.